UG‐1 has been installed in over 1,000,000 SF of cleanroom space, of which 150,000 SF was designed and certified for Class 10 space. When these areas were later tested, the results were a Class 1 System.

HEAVY DUTY. FLEXIBLE. LOAD BEARING.

UG‐1 was designed by engineers who recognized the importance of creating a strong but flexible ceiling system. The structural capability of the grid system not only allows for hang loads, but also lends 100% accessibility to the area directly above the cleanroom ceiling for ease of maintenance personnel.

One of the unique features of the UG‐1 Ceiling System is its patented tee‐slot and associated structural capabilities. The tee slot allows for the secure attachment of partitions, mini‐environments, process piping and robotic tracks with utility clips that will not damage the grid face.

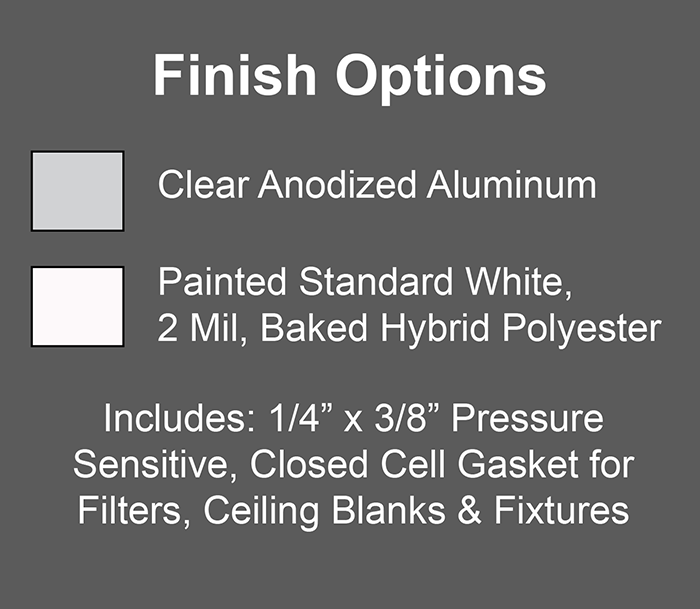

Additionally, components installed into the grid are gasketed, which ensures that the filters and blanks are sealed properly. Pre‐engineered filter and blank hold‐down clamps ensure uniform compression of gasket material to 50% of the original material thickness. UG‐1 hold‐down clamps ensure that the system will remain leak free, and provide a safe work platform for servicing your plenum space.

Hang 220 lbs with less than .063” deflection at the weakest point. Increase the point load to 3,000 lbs by simply adding a hang point to the structure above.

Companies that use UG-1 Ceiling Grid System

INFORMATION TO CONSIDER:

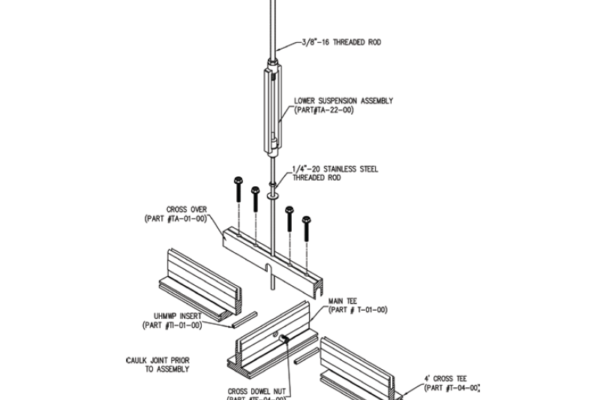

- 12 foot mains are pre‐assembled with the threaded rod, turnbuckle, crossovers and splice on the main and ready to attach to your primary hang.

- 4 foot cross tee are notched for strength which also allows for incredible efficiency in installation. When the mains are installed, the 4 foot tees can be placed and squared in less than a minute.

- Optional packaging: 12 foot mains and 4 foot cross tees are double shrink‐wrapped on cleanroom carts at the factory. This allows for the carts to be rolled onto the wipe-down room where the shrink‐wrap is removed and the wheels are taped before being moved into the area where the ceiling system is being installed.